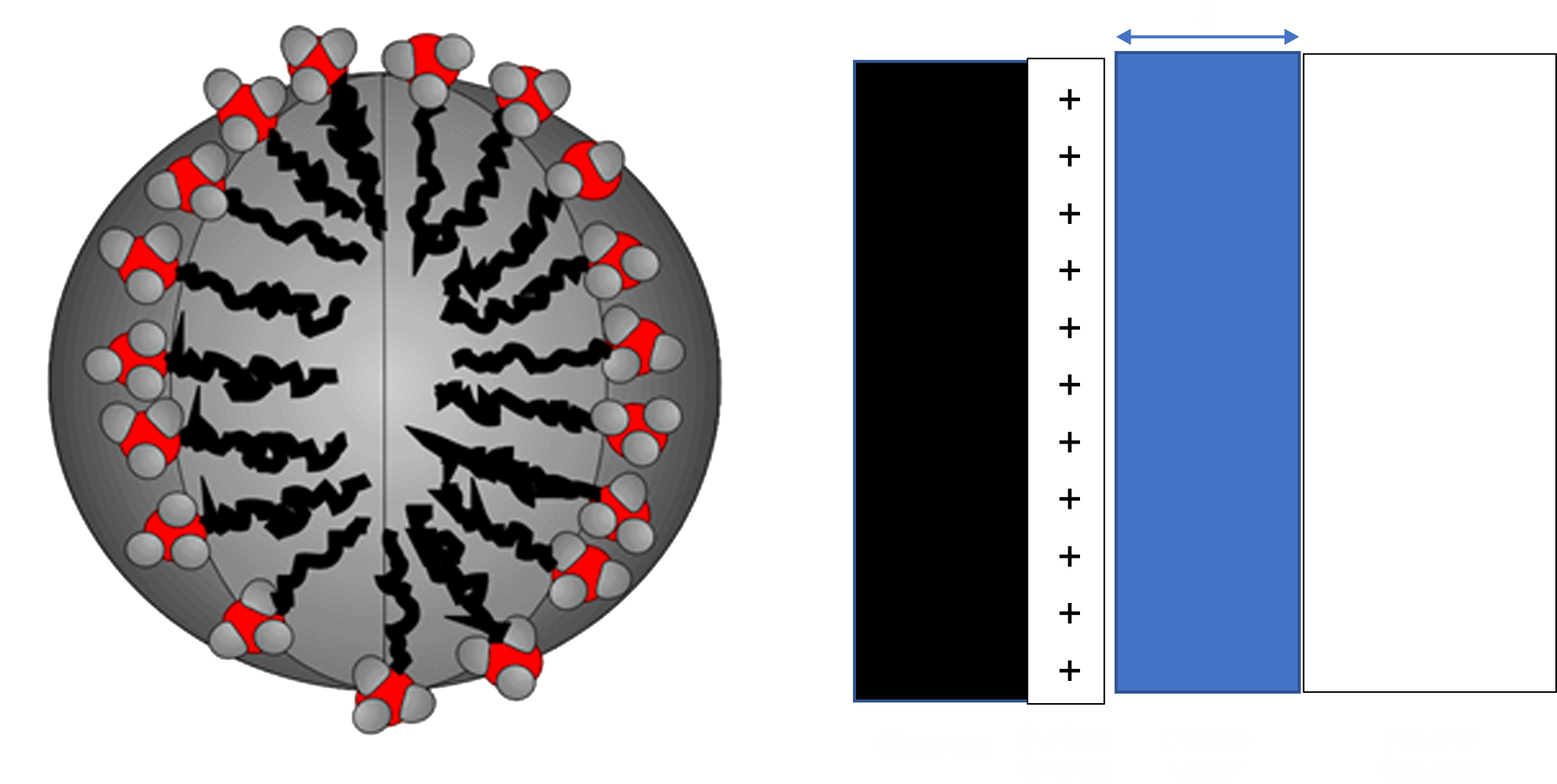

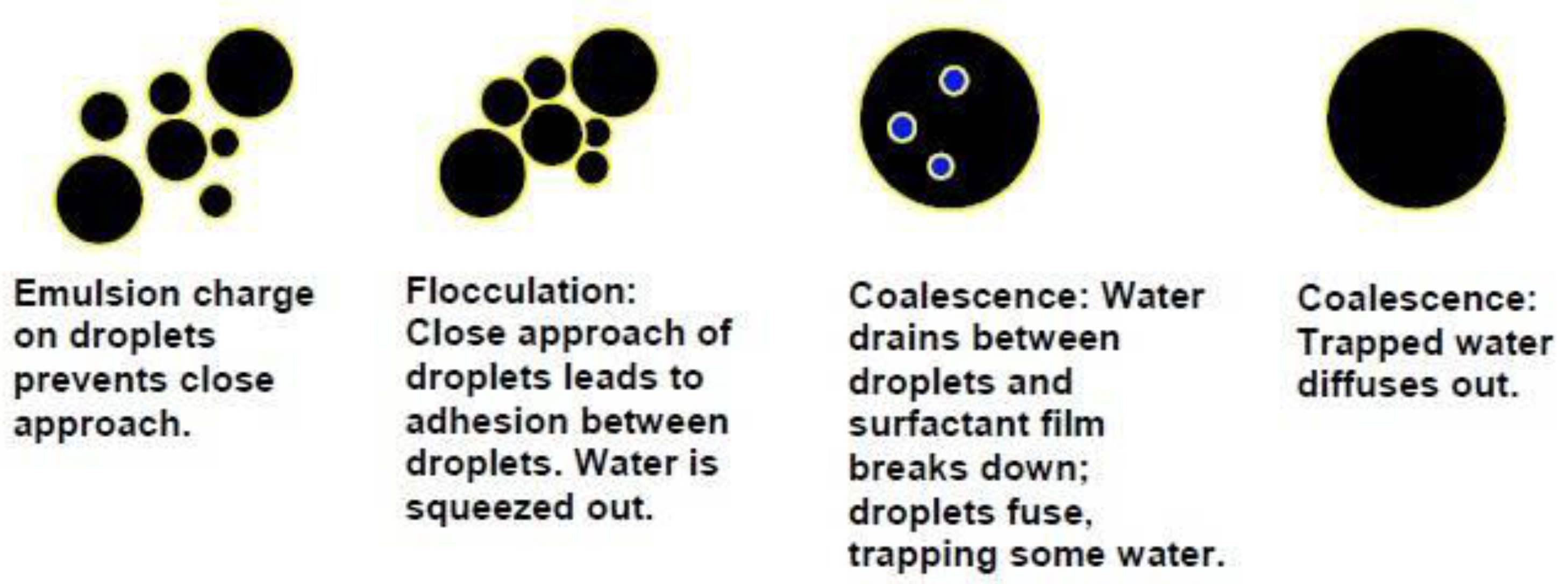

Bitumen emulsions are a versatile and environmentally superior method of binding aggregates. Bitumen must be made mobile to wet out and adhere to an aggregate. This process may be carried out by heating, cutting with solvents, or emulsification. When the wetting has occurred, the bitumen must revert to its semi-solid state. Retained solvents can create long-term softness, and if the bitumen cools too quickly, it may not allow processes like compaction. In emulsions, we have a chemical system that may be manipulated for the properties required. With bitumen, we make oil in water type emulsion. That is, water is a crucial component to ensure that evaporation is not the controlling mechanism of becoming solid chemistry is used.

Holleran, G., 1999. Analysis of Emulsion Stability and Asphalt Compatibility, Asphalt Emulsion Manufacturing Association, International Symposium on Asphalt Emulsion Technology, 1999

Holleran, G., Hicks, R.G., Reed, J.R., 2002. Effect of Particle Size and Distribution on Slurry Surfacing Microsurfacing Performance, International Slurry Surfacing Association, International Conference Berlin,Germany, 2002.

AR Thermosets manufactures various grades of Bitumen Emulsions. We have been in the business of manufacturing Bitumen Emulsions since 1996.

Currently ART is on its Third Generation of Bitumen Emulsions. AR Thermosets works with over 12 different Emulsifiers and Polymers to deliver the perfect Emulsion – that is cost-effective and performance-effective!

©COPYRIGHT 2021 – 2024 | AR THERMOSETS | ALL RIGHTS RESERVED