Close

Close

Bitumen emulsions 1000 are a versatile and environmentally superior method of binding aggregates. The material is stabilized by a surfactant system- a bit like shampoo.

The BE2000 Series was developed as a high-performance evolution of the BE1000 Series, engineered to optimize the chemical interaction between aggregates, fillers, and emulsions for superior and versatile road solutions.

The BE3000 Series was developed to meet the demands of high-congestion top-surface applications, offering superior binding strength, heat resilience, low-temperature flexibility, ductility, and elastic recovery.

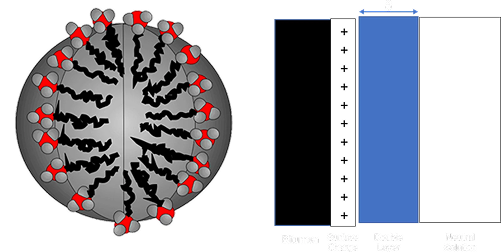

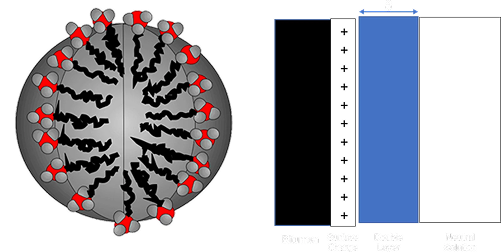

Bitumen emulsions are a versatile and environmentally superior method of binding aggregates. Bitumen must be made mobile to wet out and adhere to an aggregate. This process may be carried out by heating, cutting with solvents, or emulsification. When the wetting has occurred, the bitumen must revert to its semi-solid state. Retained solvents can create long-term softness, and if the bitumen cools too quickly, it may not allow processes like compaction.

In emulsions, we have a chemical system that may be manipulated for the properties required. With bitumen, we make oil in water type emulsion. That is, water is a crucial component to ensure that evaporation is not the controlling mechanism of becoming solid chemistry is used.

WhatsApp us